We are finally back from the final exam period and the winter break and we are excited to announce that we are all back to work again for the upcoming competition. Here is what the different subteams were able to achieve this month.

SOFTWARE SUBTEAM:

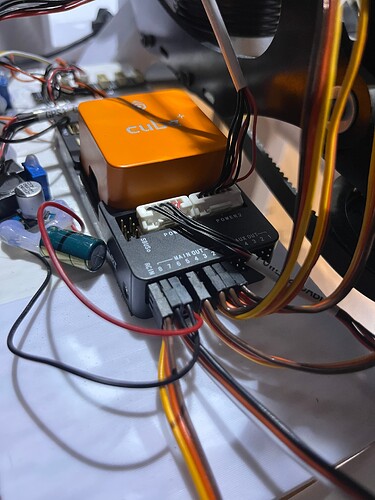

This month we have been facing issues with our radio telemetry and the range. Hence we decided to use a cellular system which involves putting on a raspberry pie on our aircraft, establishing a connection with the cube orange through which we can stream our telemetry. We are also looking into streaming videos from our cellular system so that we are able we’re able to run a machine learning model on a more powerful computer, when on ground.

MECHANICAL SUBTEAM:

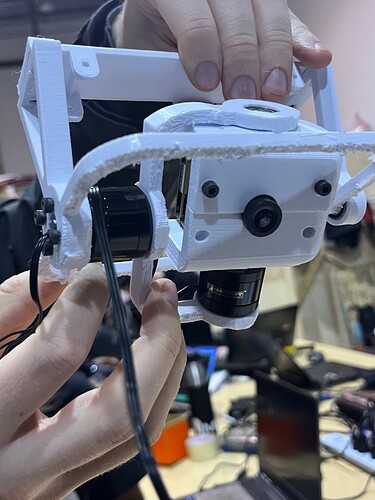

Our mechanical subteam is currently working on the design of the shell of the helicopter. After verifying that the shell is good enough through the simulation of the 3D design, we should be able to start the manufacturing process of the shells using carbon fibre and the printing of the female moulds which we would be using in the manufacturing process of the shells. We would also be re-printing our 3D printed parts by shaving down and optimising our parts to make the weight as per the competition requirement of under 15 kg.

COMPOSITE SUBTEAM:

Since we have a large helicopter and due to competition rules we have a need for a closed cabin and aerodynamic to reduce the drag. We have created a shell around the helicopter and for the first time we are building a shell out of carbon fibre composites.

ELECTRICAL SUBTEAM:

We would like to thank our cube pilot sponsorship who made it possible for us to maintain our to maintain our large fleet of aircrafts. The ability of their flight computers to easily integrate with the other avionics on our drones has allowed us to test creative solutions to this year’s competition demands.