Any special reason to use 4.1 Dev instead of a Stable version? Usually bigger frames and props are too expensive to risk, but so long as you are aware not all Dev features and changes have had suitable flight time.

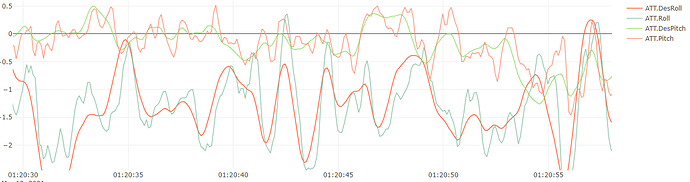

Attitude control needs work

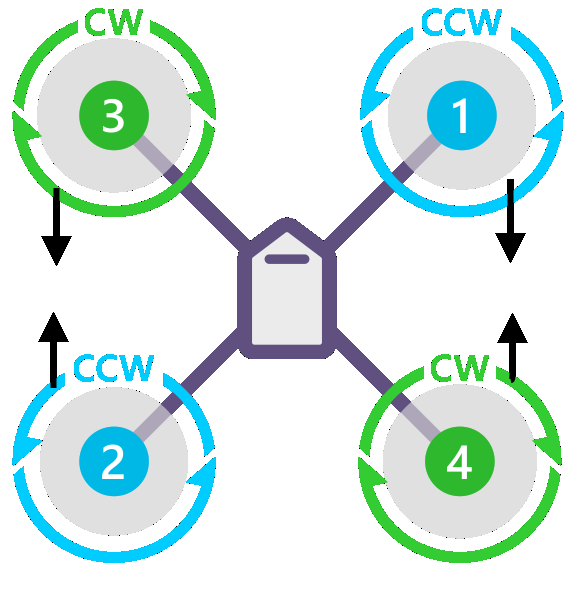

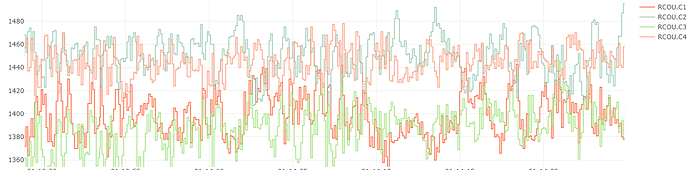

Motors 2 and 4 are typically working harder than 1 and 3, indicating a slight weight imbalance to the front.

Current monitoring is not working, best to set that up as soon as possible. It’s another worthwhile diagnostic tool. Maybe just your BATT_AMP_PERVLT,0.0489 is wrong. A Cube power brick is normally BATT_AMP_PERVLT,39.877 but you have something non-standard for the Voltage scale, so I’m guessing the current scaling will be non-standard too.

Vibrations are good, Z axis is a little higher than ideal but just something to watch out for in case it becomes an issue.

I would set these to help be as safe as you can

BATT_FS_LOW_ACT,2

FENCE_ENABLE,1

FENCE_TYPE,3

This fence setting will make you wait for a good GPS 3D fix and home position, but it’s not much to ask for one of these big craft to do a RTL properly when it needs to.

For the T-Motor Flame ESCs I’d usually advise to set these:

MOT_THST_EXPO,0.2

MOT_PWM_MIN,1100

MOT_PWM_MAX,1940

There’s some conflicting evidence out there, but so far I think the balance favours these settings.

Even rerun the ESC calibration too, just in case the ESCs do respond to that. Some doco says they can’t be calibrated and those PWM settings must be used, and some says they can ALSO be calibrated.

You’ve got ATC_INPUT_TC moving all over the place during flight. That’s OK but probably just set it at 0.2 to 0.25 for these big frames. 0.15 is the default and is quite twitchy to suit smaller more acrobatic frames.

ATC_INPUT_TC is not your core problem, it’s the attitude control.

For fixing the attitude control, I’m going to suggest a few things in sequence.

First set these, not much change here

ATC_ACCEL_P_MAX,25300

ATC_ACCEL_R_MAX,25300

ATC_ACCEL_Y_MAX,10800

ATC_RAT_PIT_FLTD,10

ATC_RAT_PIT_FLTT,10

ATC_RAT_RLL_FLTD,10

ATC_RAT_RLL_FLTT,10

ATC_RAT_YAW_FLTT,10

PSC_ACCZ_I,0.34

PSC_ACCZ_P,0.17

and lets rationalise the PIDs a bit, since they were quite different per axis and not working well anyway

ATC_ANG_PIT_P,6.0

ATC_ANG_RLL_P,6.0

ATC_RAT_PIT_D,0.00625

ATC_RAT_PIT_I,0.10

ATC_RAT_PIT_P,0.10

ATC_RAT_RLL_D,0.00625

ATC_RAT_RLL_I,0.10

ATC_RAT_RLL_P,0.10

then set up the logging for a test flight before enabling the Harmonic Notch filter:

INS_LOG_BAT_MASK,1

INS_LOG_BAT_OPT,0

Do a test flight in Althold for a minute or two, maybe a bit of gentle movement to test your RC control now, but nothing radical. Mostly we just want hover for now.

Let’s see the .bin log file from that flight.

Then we will enable the Harmonic Notch Filter and probably run Autotune if everything is working out OK.

If you get to do the above tests and want to progress, this is what you need for the next stage of Harmonic Notch filtering:

HNOTCH phase 2

INS_HNTCH_ENABLE,1 ← set this then refresh params to see the rest

INS_HNTCH_MODE,1

INS_HNTCH_REF,{hover_thrust}

INS_HNTCH_FREQ,{peak freq from FFT}

INS_HNTCH_BW,{peak_freq / 2}

INS_HNTCH_ATT,40

INS_LOG_BAT_OPT,2 - capture post-filter gyro data, test fly again to generate a new log and recheck

HNOTCH phase 3

INS_LOG_BAT_MASK,0

INS_LOG_BAT_OPT,0 - no extra logging, assumes HNOTCH is working great

but you’ll have to read up on it first and work out how to read the FFT in MissionPlanner. Best to just do the test flight and post a link to the new .bin log file

!!)

!!) but still needs improvements.

but still needs improvements.